05 May, 2025

Introduction

Synthetic leather refers to a range of man-made materials developed to imitate the appearance and texture of genuine leather while offering a cruelty-free, cost-effective, and versatile alternative. There has been an increased growth in these materials as ethical concerns, evolving consumer demands, and novel materials science progress. The two most commonly used types of synthetic leather are PU (Polyurethane) and PVC (Polyvinyl Chloride) leather. They both have inhabited distinct niches in the industries of fashion, automotive, upholstery, marine, and healthcare.

While their composition looks alike first, view comes with huge variations in their composition, feel, durability, environmental impact, and performance characteristics that would put them at a different use world. The emphasis on comfort, aesthetics, longevity or cost efficacy guides you toward choosing the right material.

What is PU Leather?

Composition and Production Process

Fabric bases such as polyester, cotton, or nylon coated with a layer of polyurethane resin are referred to as PU leather. This resin is engineered to create a copy of the way real leather feels, looks and smooths out. Modern PU leather can be embossed with intricate patterns, stacked in different ways, or treated to become softer and more breathable. Old methods tend to be less sustainable than the leather manufacturing process since they often employ water-based techniques.

Common Applications

Because of this, PU leather is quite widely used on products that need a little of both: style and comfort. PU can be adapted to more fashion items such as handbags, shoes, belts, jackets, sofas, chairs, car interiors and decorative accessories. It comes with ease of customization and a soft feel that makes it a favorite material to use for brands that want their products to flaunt luxuriousness without resorting to animal hide.

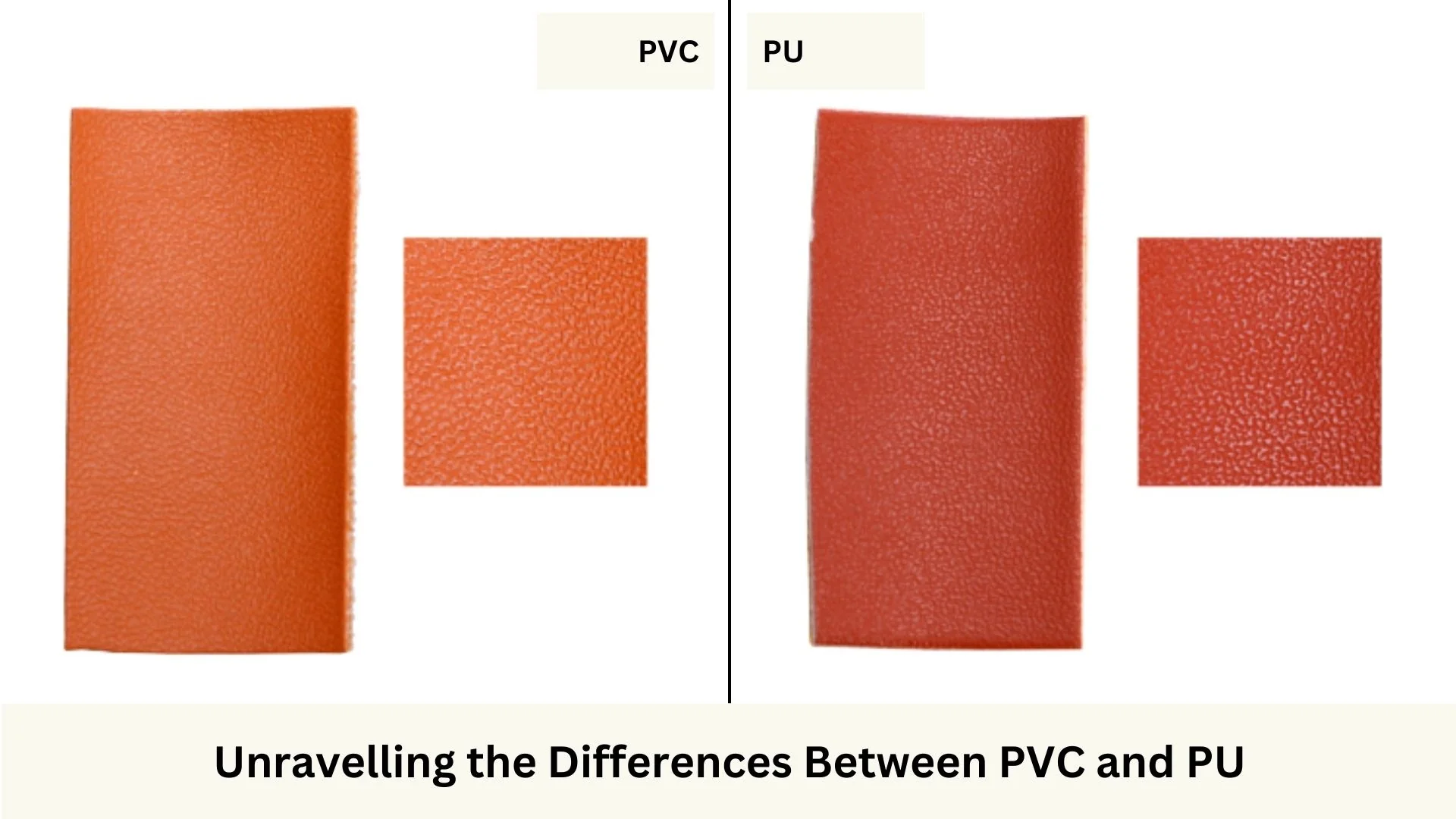

Visual and Tactile Characteristics

PU leather looks very realistic and the leather part is like real leather, smooth or glossy finish. It is soft and flexible and easy to wear for an extended period. Amid most material types, dyes tend to mingle with PU leather and absorb color quickly, endowing it with rich color variations and intricate textures.

What is PVC Leather?

Composition and Production Process

Polyvinyl chloride is laid onto a backing fabric that is reinforced with plasticizers to increase flexibility and workability, and this product is known as PVC leather. The material is tough and is resistant to moisture, stains, and chemicals and the multi-layer construction of the material can be manipulated into various thicknesses and finishes. UV, flame retardancy antibacterial, or any other additives will be included if required in the application.

Common Uses

PVC leather is robust and waterproof, hence it’s popular in marine furniture, public transportation seating, hospital beds, gym equipment and school products like backpacks and lunchboxes. For the places where durability, hygiene and ease of cleaning are more paramount than softness or luxury appearance, it is perfect.

Appearance and Feel

PVC leather has more of a structured and firmer appearance and can be manufactured with a high gloss finish. While not as soft as PU, it ensures a really good shape and thus is favored for industrial and commercial design ideas. The surface is slightly more synthetic, feeling less breathable, and better suited to short-term contact uses.

PU vs PVC: Composition and Manufacturing

Key Chemical Differences

Urethane compounds give PU natural flexibility, softness and resilience. While PVC is formed from chlorinated hydrocarbons of petroleum, coming together to create a denser, more durable surface. These chemical differences mean that each material reacts differently to stress, temperature change and wear and tear.

Environmental Impact of Production

With the development of water-based, solvent-free, plant-based formulations VOCs are also being reduced. PVC has its eco-friendliness improved by historical green additives and closed-loop recycling systems but has not yet reached the eco-friendly standard of PU.

Flexibility and Softness

PU leather has a naturally softer and more elastic form, suitable for garments and home décor where comfort and flexibility are critical. The dense structure of PVC is best suited for rigid forms and applications needing dimensional stability, including covers, panels, and external furnishing.

Durability Comparison

Performance Over Time

PVC leather is well known for resisting harsher environments such as those subjected to exposure to moisture, heat, or high friction. Once used, it is tough and does not degrade easily, breaking only when it is cut. Although PU leather is durable, it is more vulnerable to scratches, peelings, and UV damage particularly if exposed to harsh environments without proper care.

Resistance to Peeling, Cracking, and UV Exposure

This naturally imparts resistance to PVC’s common wear issues, such as cracking, hardening and UV-induced fading. However, PU leather needs coatings or finishes to perform in the same way in these areas, and high quality PU can also last for several years with proper maintenance.

Breathability and Comfort

Better for Wearables and Furniture

The porous surface and soft backing of PU leather also make it more breathable than leather and, therefore, less uncomfortable to wear for long periods. It’s a perfect choice for a jacket, car seat, sofa, or office chair. It also will benefit users by creating less, or no sweat, accumulation and a more natural leather-like experience.

Impact on Heat Retention and Sweat

PVC, being a nonporous surface, tends to trap heat and moisture making things sweaty and uncomfortable, especially in the high light regions or prolonged usage. This same property, however, makes it perfect for cold conditions, by helping to retain warmth.

Cost Differences

Affordability

Instead, PVC leather is either cheaper or easier to produce because the costs of raw materials or manufacturing are lower. For such large scale commercial projects or budget-conscious consumers, it becomes an obvious choice.

Long-Term Cost Implications

We agree that PU leather might be more expensive from the initial point of sales but it can be more comfortable and more stylish and more user satisfying, which is the key to compete in premium markets. PVC synthetic leather also has a long service life with low maintenance and durability and in public or industrial environments where it is used replacements are costly and require frequent cleaning, this gives long term value.

Maintenance and Cleaning

Care for PU and PVC Leather

Both materials are pretty low maintenance and just a damp cloth and milder soap work well for everyday cleaning. PU should be kept away from alcohol-based cleaners and direct sun to not peel but PVC leatherette can take disinfectants, steam cleaning and rougher cleaning routines.

Stain Resistance and Ease of Cleaning

PVC leather is more stain-resistant and chemically resistant and is therefore best used in the healthcare, hospitality, and childcare sectors. Since PU is easier to clean than real leather, however, it is also more fragile, and special caution must be taken when dealing with oil-based or colored stains.

Aesthetic Differences

Texture, Color Absorption, and Finish

PU leather provides a natural leather look, with better grain replication and the ability to absorb dyes deeply. Thus richer 'tones', smoother gradations and more refined finishes are achieved. Whereas PVC supports bolder colors and high gloss finishes but has a synthetic feeling to it.

Use in Fashion and Automotive Design

In clothing and interiors for premium cars, PU leather is used due to the importance of elegance and realism. In commercial vehicles, public seating, institutional furnishings, and good appearance in terms of a clean and uniform appearance has superseded the luxurious feel in favor of PVC.

Common Use Cases and Industry Preferences

Industries Preferring PU

The richness in textures, comfort and style makes value PU leather a choice for sectors including apparel, luxury furniture and automotive. When the look and gentle feel are very important to the brand identity, high-end brands often select PU to meet the product needs.

Industries Preferring PVC

PVC is a moisture-resistant, strong, hygienic surface material that is used by industries such as marine, medical, hospitality and transportation. Hence, it is especially in high-traffic areas where there are regular sanitary facilities.

Real-World Product Examples

Designer handbags (vegan fashion brands), high end high chairs and top car seat covers are made from PU leather. Train seats, school bags, dental chairs, etc. are made of PVC leather, and also outdoor lounge furniture.

Allergic Reactions and Safety Concerns

Skin Sensitivity and Toxicity Issues

When your product is PU leather, it is considered hypoallergenic and also safe to most users. Also nontoxic is PVC, from proper manufacture meeting safety regulations (e.g., REACH, RoHS). While lower-grade PVC may have some plasticizers that do cause sensitivity in rare cases, it is important to verify compliance.

Safe Use in Home and Office Environments

If procured from reputable manufacturers, PU and PVC leathers are also safe for indoor environments. Phthalates and heavy metals are avoided in current formulations to be safe for family use, pets, and long term use.

Lifespan and Wear Patterns

Product Longevity

Commercially, PVC synthetic leather will survive 10+ years and barely looks worn out. In controlled, low-impact environments, PU leather can last just as long as leather. Especially for fashion and indoor décor.

Signs of Aging and Prevention

If left unattended, PU can peel, crack, or fade, and PVC may become stiffer or lose flexibility with age. With regular cleaning, conditioning, and avoiding prolonged UV exposure, both materials can have considerable usable life.

PU vs PVC: Which One is Right for You?

Summary of Differences by Use Case:

-

PU Leather: Ideal for fashion, home interiors, accessories, and automotive interiors where touch, comfort, and appearance are priorities.

-

PVC Leather: Best suited for marine, healthcare, hospitality, gym equipment, and industrial environments requiring resilience, easy cleaning, and moisture resistance.

Where to Buy PVC Leather? Try Rock Uniquoters – Global Supplier

Rock Uniquoters is a leading manufacturer and exporter of high-quality PVC leather, catering to With expertise in high-quality PVC leather, Rock Uniquoters is a top manufacturer and exporter that serves various industries across the world. Rock Uniquoters' PVC leathers are famous for their consistency, strength and long life and are specifically aimed at helping harsh environments such as automotive, marine, healthcare, and hospitality and education. The goal of their products is to be durable, water resistant, and easy to maintain and therefore their products work perfectly for commercial and institutional use.

Rock Uniquoters has a range of colors from classics and neutrals to deep, earthy tones to bold accents and custom tones to match branding or design themes. Available with smooth and glossy finishes and embossed grains, their PVC leather is diverse in textures. Depending on the application, clients have options of multiple thicknesses from 0.6mm to 1.4 mm. Matt, semi-gloss, high gloss and ultra matt finishes are available to enable designers and product manufacturers the freedom to create products that are both functional as well as visually striking.

FAQ

1. Is PU or PVC leather better for car seats?

PU offers a more refined look and comfort, while PVC provides greater durability and resistance to wear and spills.

2. Which is more environmentally friendly?

PU, especially with water-based or bio-based formulas, is evolving to be more eco-friendly. PVC, while longer-lasting in some contexts, has a higher environmental footprint.

3. Can PU or PVC leather peel?

PU may peel over time with wear, especially if not properly cared for. PVC is more resistant to peeling but may harden or show surface wear over the years.

4. How can I tell the difference between PU and PVC?

PU is softer, more elastic, and has a more natural matte texture. PVC is firmer, shinier, and feels more synthetic.

5. Is either type of leather waterproof?

PVC is fully waterproof, making it ideal for wet environments. PU is water-resistant but may absorb moisture over time.