02 October, 2025

Introduction to Faux Leather

Faux leather, also known as synthetic or “vegan” leather, is a man‑made material crafted to mimic the appearance, texture, and often smell of genuine leather. Faux leather is also referred to as imitation leather, a term used for synthetic or vegan leather designed to replicate the look and feel of real leather.

It is typically made using synthetic polymers such as polyurethane (PU) or polyvinyl chloride (PVC), combined with fabric backings or other supports. Because it doesn’t require animal hide, faux leather is usually more affordable, easier to maintain, and considered more animal‑friendly. Faux leather is used widely in fashion (jackets, shoes, bags), upholstery, car interiors, and accessories. As interest in sustainable, cruelty‑free, and cost‑effective alternatives grows, so does the popularity of faux leather. However, it’s important to explore how it compares to genuine leather in terms of quality, durability, environmental impact, and suitability.

Understanding Real Leather

Real leather (often called genuine leather, full‑grain leather, top grain, etc.) comes from animal hides. Real leather is made from animal skin, which is the natural hide of animals, distinguishing it from synthetic or composite materials. Most commonly, it is sourced from cows cow leather is especially prevalent due to its availability as a byproduct of the meat industry and is valued for its superior durability. The hide is processed through tanning, finishing, dyeing, sometimes embossing or buffing, and then shaped into the end product. Real leather is prized for its natural texture, strength, fragrance, and its ability to age beautifully often developing a patina, a sheen or character that improves with use.

Real leather is breathable, because of its fibrous structure, helping regulate temperature and moisture. It can be more expensive due to the cost of raw materials, the labor involved in the tanning process, and the quality control required. The tanning and finishing steps can also influence the appearance, feel, and lifespan of the leather piece.

Types of Leather

There are several standard types (or grades) of leather. Understanding them helps when you're comparing real vs fake leather or choosing real leather products.

Full Grain Leather

-

Definition: Leather that uses the full thickness of the hide, with the grain kept intact. Only the hair side is removed; imperfections, scars, and natural markings remain.

-

Characteristics: Extremely durable, very high quality, breathes well, develops patina over time.

-

Applications: Premium furniture, high‑end bags, luxury shoes.

Top Grain Leather (Corrected Grain)

-

Definition: Comes from the top layer of the hide as well, but the surface is sanded or buffed to remove imperfections, then often pigmented or treated for uniformity.

-

Characteristics: More uniform appearance, somewhat less rugged, still durable, more refined look than full grain.

-

Applications: Mid‑to‑high end products where look matters more than raw ruggedness (fashion handbags, upholstery).

Split‑Grain Leather

-

Definition: The hide is split, so the top grain is removed. The lower layers are used, sometimes with treatments or finishes.

-

Characteristics: Less strong than top or full grain, may be more flexible, sometimes used for suede (if the flesh side is finished).

-

Applications: Suede goods, cheaper leather items, linings, etc.

Genuine Leather (as a Grade Term)

-

Definition: This term can be confusing. Sometimes it refers to any leather that's not synthetic; other times it indicates a lower grade of real leather (split or processed leather).

-

Characteristics: Varies greatly; genuine leather might be decent quality, or it could be low grade depending on how it is processed.

-

Applications: Affordable leather goods, belts, lower cost shoes, etc.

Bonded Leather

-

Definition: Made from leftover leather scraps, ground up, mixed with PU or other binders, and formed into sheets with a backing. Sometimes called reconstituted leather.

-

Characteristics: Contains only a small amount of real leather fibers; a polyurethane coating is often applied to enhance its appearance and durability; tends to have less longevity, prone to peeling or delaminating; looks less like natural leather over time.

-

Applications: Cheap furniture, low‑cost goods.

Bicast Leather

-

Definition: A type of split leather that has been coated or laminated on top with a layer of polyurethane or similar. It is embossed or stamped to look like top grain.

-

Characteristics: Has the look of fine leather initially, but the top polyurethane or coating can crack, peel, or degrade with time and exposure.

-

Applications: Furniture upholstery and budget items where appearance is prioritized over long lifespan

Faux Leather Options / Types

When it comes to faux leather, there are different materials and manufacturing methods. Faux leather is a synthetic alternative to real leather, offering a more affordable and animal-friendly option. Key fake leather types include:

-

PU Leather (Polyurethane Leather): More flexible, softer feel, often looks more similar to real leather, easier to work with.

-

PVC Leather (Polyvinyl Chloride Leather): Often cheaper, more rigid, more waterproof, but can be less breathable and more chemically intensive in production. Some types of PVC leather include a foam layer beneath the surface, which can reduce breathability and affect overall comfort.

Environmental Considerations

Both real leather and faux leather have environmental impacts. Comparing them involves trade‑offs.

Impact of Real Leather

-

The tanning process uses large volumes of water and often strong chemicals (e.g. chromium, sulfides) that can pollute water sources if not treated properly.

-

Animal agriculture contributes to greenhouse gas emissions, deforestation, land use, feeding and raising livestock.

-

On the positive side, leather is a by‑product of the meat industry in many cases, meaning that hides are used rather than wasted.

Impact of Faux Leather

-

Synthetic leather often depends on fossil‑based materials (PU, PVC), which consume energy, produce emissions, and may use plasticizers or other chemicals that are toxic.

-

PVC in particular is associated with release of harmful chemicals during production and after disposal. PU is generally considered a less bad option, but still involves environmental costs.

-

Faux leather is typically not biodegradable; when it ends up in landfill, it may degrade slowly and sometimes release microplastics or other pollutants.

Comparing Real vs Faux

-

Durability: Real leather generally lasts longer; high quality real leather can last decades if cared for. Faux leather may degrade faster, especially in harsh conditions or with heavy use.

-

Lifecycle: A longer lifespan can offset some of the environmental cost of real leather. If faux leather must be replaced frequently, that adds waste and more production impact.

-

Production footprint: Real leather has heavy environmental cost in tanning; faux leather has cost in plastic and chemical manufacture. Which is better depends a lot on sourcing, treatment, how the product is used, and end‑of‑life handling.

Ultimately, the ideal material for any application is one that balances durability, environmental impact, and the specific needs of the user.

Structure and Composition

Here are more details about what gives real and faux leathers their properties.

-

Real Leather Structure: Comprised of the hide’s layers. The grain is the top side, with dense fibers, responsible for strength, texture. The grain layer of real leather is often smooth and supple to the touch, enhancing its natural appearance and tactile appeal. Inner layers (flesh side, split side) are looser, softer. Leather fibers can stretch and adapt over time, which helps the leather conform to the user's shape and improves comfort and fit. Different parts of the hide have different thicknesses, textures. The finishing treatment (aniline, semi‑aniline, pigmented, etc.) affects color, protection, water resistance.

-

Faux Leather Composition: Typically a fabric base (like cotton, polyester, or rayon) coated with PU or PVC. Some types have foam layers for padding. The coating may be printed or embossed to mimic grain. Thickness, backing, quality of coating determine feel, durability, breathability.

-

Breathability & Comfort: Real leather (especially full grain) allows moisture vapor to pass, helping comfort. Faux leather often less breathable, sometimes hotter, can trap moisture. But some high‑quality faux leathers are engineered to be more breathable.

-

Appearance & Ageing: Real leather can develop patina, softens, may get small wrinkles, marks that many find attractive. Faux leather tends to maintain appearance longer initially (no scuffs show as much), but may crack, peel, fade over time.

Breathability and Comfort

Breathability is a key factor when it comes to the comfort of leather products, especially in items like clothing, upholstery, and accessories that are in close contact with the skin. Genuine leather, particularly full grain leather, is renowned for its natural breathability. The unique structure of grain leather allows for better air circulation and moisture-wicking, helping to keep you cool and comfortable during everyday use.

Synthetic leather, such as PU leather and PVC leather, can vary in breathability depending on the materials and manufacturing process. PU leather is generally considered more breathable than PVC leather due to its porous structure, making it a popular choice for accessories, handbags, and apparel where comfort is a priority. However, this increased breathability can also mean PU leather is more susceptible to stains and water damage if not properly treated.

Vegan leather made from plant based materials is emerging as a breathable and eco-friendly alternative to both natural leather and traditional synthetics. These innovative materials can offer a comfortable feel while reducing environmental impact.

Proper care, such as cleaning with a damp cloth and conditioning as needed, can help maintain the breathability and comfort of both genuine and synthetic leathers. For leather goods like shoes and handbags, choosing a breathable material helps prevent moisture buildup and promotes a healthier environment for your skin. Worth noting, some advanced synthetic leathers are engineered to closely mimic the breathability of natural leather, providing a comfortable and durable option for those seeking alternatives to animal products.

Comparing Faux and Real Leather: Pros & Cons

Here’s a side‑by‑side view to help assess which suits your needs.

| Feature | Real Leather | Faux Leather |

|---|---|---|

| Cost | Higher up front | Lower cost initially |

| Durability / Lifespan | Generally much longer, especially with quality and care | Shorter; may require replacement sooner |

| Maintenance | Needs conditioning, protection, but ages nicely | Easier to clean, less conditioning needed, but may degrade in heat/UV |

| Appearance | Natural, unique marks, patina | Uniform, can look very similar depending on quality, but less character over time |

| Environmental Impact | Animal agriculture, tanning pollution, but hides often by‑products | Plastic/chemical production, disposal issues; newer plant‑based options may mitigate |

| Animal Welfare | Involves animals (unless sourced as by‑product) | Animal‑free choice |

| Breathability & Comfort | Generally better | Often less breathable, can feel hotter or “plastic‑like” |

Price and Value

The price of leather products can vary widely based on the type and quality of leather used. Genuine leather, especially full grain leather, typically commands a higher price due to the premium materials, skilled craftsmanship, and durability it offers. This makes full grain leather a sought-after choice for those looking for long-lasting value in their leather goods.

On the other hand, synthetic leather options like PU leather and PVC leather provide a more affordable alternative without sacrificing style or functionality. These materials are often used in furniture manufacturing and upholstery, offering a cost-effective solution that still delivers on durability and appearance.

When considering value, it’s important to look beyond the initial price tag. Well-made leather goods from responsible brands can last for many years with proper care, making them a worthwhile investment. The durability of quality grain leather or high-grade synthetic leather means fewer replacements over time, which can save money in the long run.

Environmental impact and sustainability are also factors that influence the value of leather products. Some consumers are willing to pay a premium for eco-friendly or responsibly sourced leather, reflecting a growing awareness of the environmental footprint of both the meat industry and leather production. Ultimately, the best value comes from choosing materials and brands that align with your needs, budget, and values, while ensuring proper care to maximize the lifespan of your leather items.

Additional Considerations

When deciding between faux vs real leather, beyond just the material, think about:

-

Quality of finishing & craftsmanship: A well‑made faux leather product can outperform a poorly made real leather one. Seams, stitching, backing, coating quality, and especially attention to detail all matter in both real and faux leather products.

-

Usage environment: Will the product be exposed to sun, humidity, abrasion, or heavy use? Real leather usually performs better in heavy use; faux leather may fade or crack when exposed to extremes.

-

Cost over time: While faux leather might cost less now, replacement frequency and maintenance might tip total cost.

-

Source & transparency: For real leather: are the hides ethically sourced, what tanning methods used, are waste & emissions managed? For faux leather: what polymers, coatings, and chemicals are used, and can they be recycled, or safely disposed?

-

Style preferences: If you value natural imperfections, texture, patina real leather might be for you. If you want uniformity, vibrant color, consistent texture, faux leather might hit more of your needs.

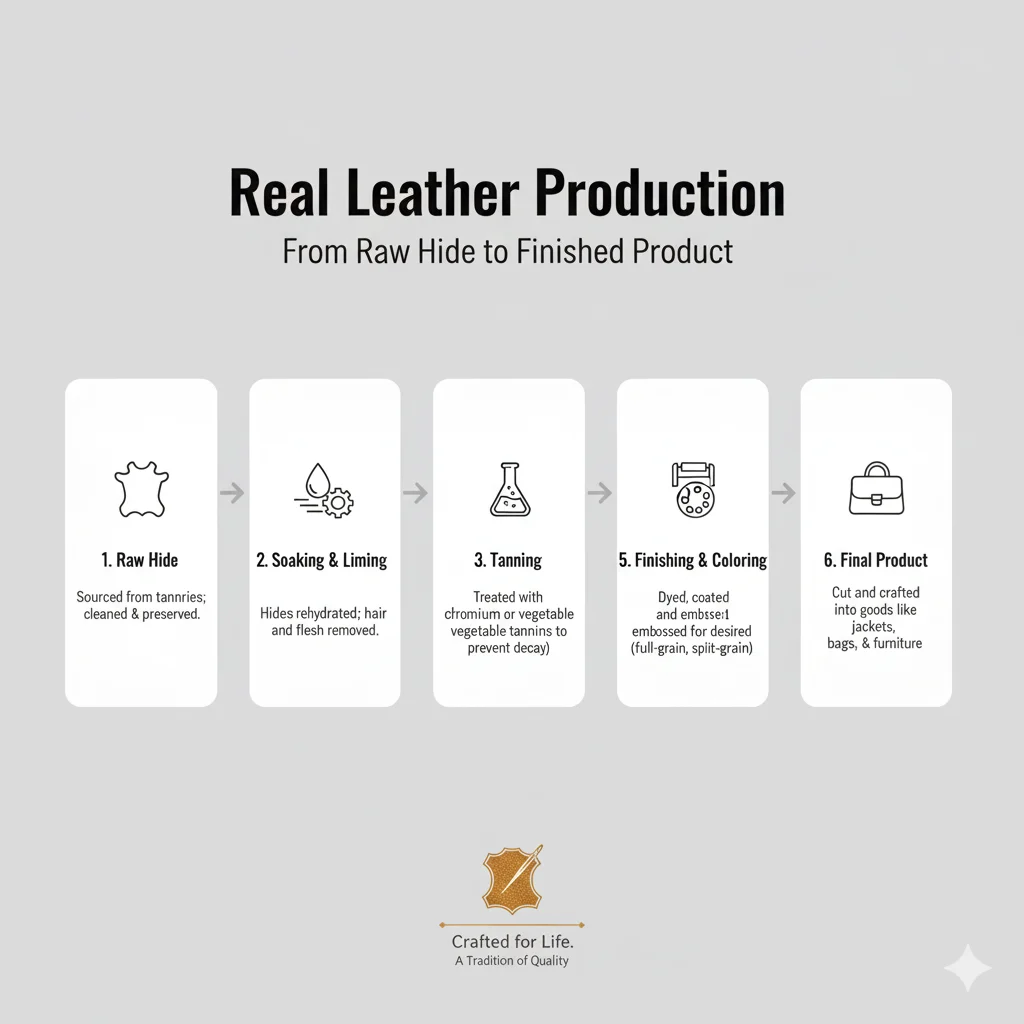

Leather Production: Real vs Artificial

Leather, whether real or artificial, undergoes a series of steps to transform raw materials into usable sheets for fashion, upholstery, and accessories. Leather is made by processing animal hides or alternative materials through tanning, finishing, and other manufacturing techniques to achieve the desired texture and durability. Understanding the production processes highlights both the craftsmanship behind real leather and the innovation of synthetic alternatives.

Real Leather Production

Raw Hide Acquisition

- Leather starts with animal skins, typically from cattle, goats, or sheep. The hides are carefully removed, then salted or preserved to prevent decomposition during transport.

Preparation

- Hides are cleaned, dehaired, soaked, and treated with liming and deliming to remove unwanted proteins and prepare the surface for tanning.

Tanning

-

Tanning stabilizes the hide, preventing decay.

-

Chrome tanning is fast, widely used, and produces soft, flexible leather.

-

Vegetable tanning is slower, uses natural plant extracts, and results in leather that develops a unique patina over time. Each method differs in environmental impact and aesthetic qualities.

Dyeing & Coloring

- Leather is colored using dyes or pigments. Options include aniline (maintains natural look), semi-aniline, and fully pigmented finishes.

Finishing & Coating

- Buffing, embossing, and adding protective coatings enhance appearance and durability. Coatings improve resistance to water, UV rays, and stains.

Final Processing

- Leather is cut, stitched, and assembled into finished goods like bags, shoes, jackets, or furniture.

Artificial (Faux) Leather Production

Base Material Creation

- Faux leather usually starts with a fabric base, commonly polyester or cotton, which provides strength and flexibility.

Coating

- The fabric is coated with PVC (polyvinyl chloride) or PU (polyurethane) to replicate the texture and appearance of natural leather.

Texturing & Embossing

- Surfaces are embossed or printed to mimic natural grain patterns. This step allows consistent and customizable textures.

Coloring & Finishing

- Dyes, pigments, and finishes are applied to achieve the desired color, sheen, and durability. Modern faux leather can also include water, UV, and stain-resistant coatings.

Final Processing

- Similar to real leather, the sheets are cut, stitched, and assembled into consumer products.

Each stage can affect environmental impact, cost, texture, durability.

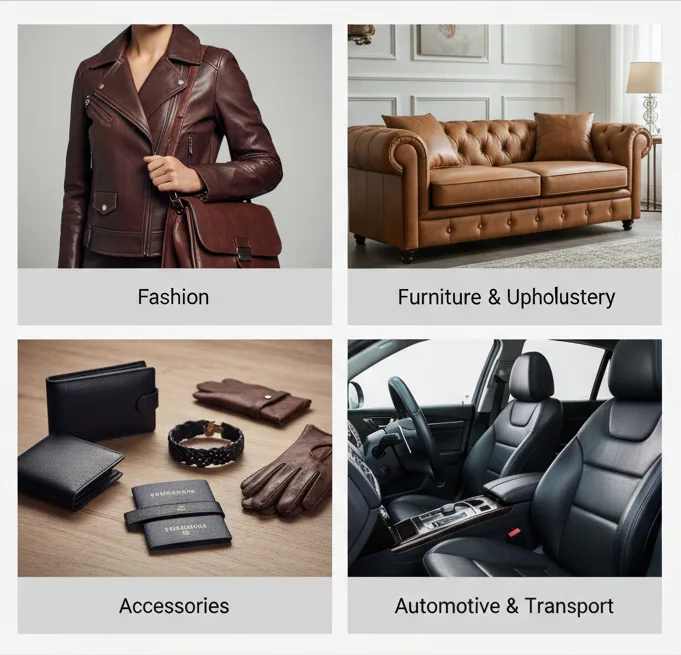

Leather Applications

Leather (real or faux) is used in many contexts. Understanding the use helps decide which material is better.

-

Fashion: Jackets, shoes, bags, belts. Real leather often used for premium pieces; faux leather for trend pieces, statement styles, or vegan fashion.

-

Furniture & Upholstery: Sofas, chairs, car interiors. Real leather luxury furniture; faux leather used for cost, ease of cleaning, color options.

-

Accessories: Wallets, belts, watch straps. Depending on tactile quality desired, cost, lifespan.

-

Automotive & Transport: Car seats, dashboards. Real leather adds prestige but maintenance and heat issues; faux leather used widely for trims, seats in lower or mid‑range models.

Leather Care

Proper care can extend the life of both real and faux leather:

-

Cleaning: Wipe with damp cloth; use mild cleaners specifically for leather. Avoid harsh detergents or solvents.

-

Conditioning (for real leather): Use leather conditioner or oils to keep leather supple and prevent drying or cracking.

-

Protection: Keep away from direct, prolonged sun; avoid moisture exposure; use protective sprays or coatings if needed.

-

Storage: Store in breathable covers; avoid plastic wraps that trap moisture.

-

Repair: Minor scratches, scuffs can often be addressed with repair kits or leather balm; for faux leather, more limited repair options.

Leather Quality

How to assess quality:

-

Feel & smell: Real leather has a distinctive natural smell; faux leather often smells more chemical or plastic. Feel should be supple, not overly plasticky or stiff.

-

Grain and texture: Full grain will show natural grain, pores, small blemishes. Fake leather grain is more uniform.

-

Thickness & backing: Thicker hides or better backing add durability.

-

Finish and coating: A protective surface helps resist stains and wear.

-

Edge finishing & stitching: Clean edges, well‑stitched seams, reinforced areas improve quality and life.

Leather Terminology

Knowing leather terms helps make informed purchases. Some terms to know:

-

Full grain, top grain, split grain

-

Genuine leather (often lower grade)

-

Bonded leather, bicast leather

-

Aniline, semi‑aniline, pigmented leather

-

Vegetable tanning vs chrome tanning

Leather Industry

The leather industry is a dynamic and multifaceted sector that spans from sourcing raw materials to crafting finished products. Driven by global demand for leather goods—ranging from clothing and accessories to upholstery and automotive interiors the industry continually adapts to changing consumer preferences and technological advancements. Synthetic leather, including PU leather and PVC leather, has become a major component of the modern leather industry. These synthetic materials are created through a manufacturing process that combines substances like polyurethane and polyvinyl chloride with fabric or foam layers to produce a material that closely resembles genuine leather. Companies like Rock Uniquoters, a leading PVC leather manufacturer and supplier, offer a wide range of high-quality leather with various textures, including embossed and paper textures, catering to industries such as automotive, fashion, transport, footwear, and home décor. This innovation has made leather goods more accessible and affordable, while also offering a durable and versatile alternative to traditional animal hides.

However, both genuine and synthetic leather production can have significant environmental implications, such as water pollution and waste generation. In response, responsible brands are adopting more sustainable practices like Rock Uniquoters, including the use of eco-friendly materials and improved manufacturing processes to reduce their environmental footprint. Innovation is at the heart of the leather industry, with ongoing research into new materials and technologies aimed at enhancing the quality, durability, and sustainability of leather products. As consumer demand for sustainable and ethically produced goods grows, the industry is increasingly focused on transparency, responsible sourcing, and minimizing its impact on the environment.

Leather Innovation

Innovation in the leather world is rapidly transforming the way we think about materials, sustainability, and performance. Researchers and manufacturers are constantly seeking new ways to create more sustainable, durable, and versatile leather products.

One exciting area of development is the use of plant based materials, such as mushroom-based leather and pineapple leaf leather, which offer a renewable and eco-friendly alternative to traditional animal leather. These materials are designed to reduce environmental waste and provide a sustainable option for consumers who want to avoid animal products.

Synthetic leather, including PU leather and PVC leather, is also evolving. Advances in manufacturing processes and materials are making these synthetic alternatives more breathable, durable, and sustainable than ever before. Features like stain resistance, better air circulation, and improved moisture-wicking are being incorporated into modern leather goods, enhancing both comfort and practicality.

The use of recycled materials and waste reduction strategies is becoming more common, helping to minimize the environmental impact of leather production. Innovative treatments and finishes are also being developed to improve air circulation and extend the lifespan of leather products, making them more suitable for everyday use.

As the leather industry continues to innovate, the focus on sustainability and performance will shape the future of leather manufacturing, offering consumers a wider range of high-quality, environmentally responsible options.

Sustainable Leather & Leather Alternatives

Because of environmental, ethical, and health concerns, many brands and consumers are seeking more sustainable leather options.

-

Plant‑based / natural fibre leathers: Made from cactus, pineapple leaf fibre (Piñatex), mushrooms, etc. These try to reduce reliance on plastics and chemicals.

-

Better tanning practices: Using vegetable tanning, chrome‑free processes, reducing wastewater, reusing water, better chemical handling.

-

Recycled leather & upcycling: Using scrap leather, rehabilitating old leather goods.

-

Transparency & certifications: Certifications for animal welfare, environmental standards, chemical safety.

Leather Education & Resources

To make better decisions:

-

Learn leather grades (full grain etc.) so you know what you’re buying.

-

Read labels and ask brands: What material is used, how is it processed, what chemicals, what is durability, what is disposal / recycling policy.

-

Try products in person if possible to feel the difference.

-

Follow sustainability reports and research on new materials.

Conclusion

Choosing between real and faux leather is not a simple "good vs bad" decision. It involves trade‑offs around cost, durability, appearance, comfort, ethics, and environmental impact. If your priority is longevity, natural feel, and willingness to invest in care, high‑quality real leather may suit you. If you prefer affordability, animal‑free materials, easy maintenance, or more color/finish variability, faux leather or newer plant‑based alternatives might be better.

Whatever you choose, focus on quality (finish, craftsmanship), sourcing, care, and how long you realistically expect the item to last because a well cared for product, real or synthetic, is always more sustainable than one that gets discarded quickly