03 November, 2025

Walk into any luxury accessories store, and you'll notice stunning leather pieces with intricate patterns that catch your eye. Many of these beautiful items feature embossed designs that add texture, character, and sophistication. But have you ever wondered how manufacturers create these detailed patterns on leather surfaces?

Understanding the embossing process reveals a fascinating blend of traditional craftsmanship and modern technology. Whether you're shopping for embossed leather handbags, considering a custom embossed leather wallet, or simply curious about leather manufacturing, this guide explains everything you need to know.

What is Embossed Leather?

Embossed Leather refers to any leather that has had a pattern or design pressed into its surface using heat and pressure. This technique transforms plain leather into textured material with raised or indented patterns that enhance both appearance and functionality.

The embossing process serves multiple purposes in the leather industry. Manufacturers use it to create uniform grain patterns across hides, replicate expensive exotic skins affordably, hide natural imperfections, and add decorative elements to finished products.

Unlike painting or printing, embossing physically alters the leather's structure. The patterns become permanent features that won't peel or fade over time, making them ideal for products that experience regular wear.

Why Do Manufacturers Emboss Leather?

Leather embossing isn't just about aesthetics. Several practical reasons drive this manufacturing choice:

Creating Uniformity: Natural leather hides contain irregular grain patterns that vary across different sections. Embossing ensures consistency, which is particularly valuable when producing multiple items that need matching appearances.

Concealing Imperfections: Animals accumulate scars, scratches, and natural marks throughout their lives. Rather than discarding these hides, embossing allows manufacturers to cover imperfections while reducing waste and maintaining sustainability.

Replicating Exotic Patterns: Genuine crocodile embossed leather or alligator embossed leather products cost significantly less than authentic exotic skins. Embossing provides the luxurious appearance without the premium price tag or ethical concerns.

Brand Personalization: Many companies use embossing to add logos, signatures, or unique patterns that distinguish their products in competitive markets.

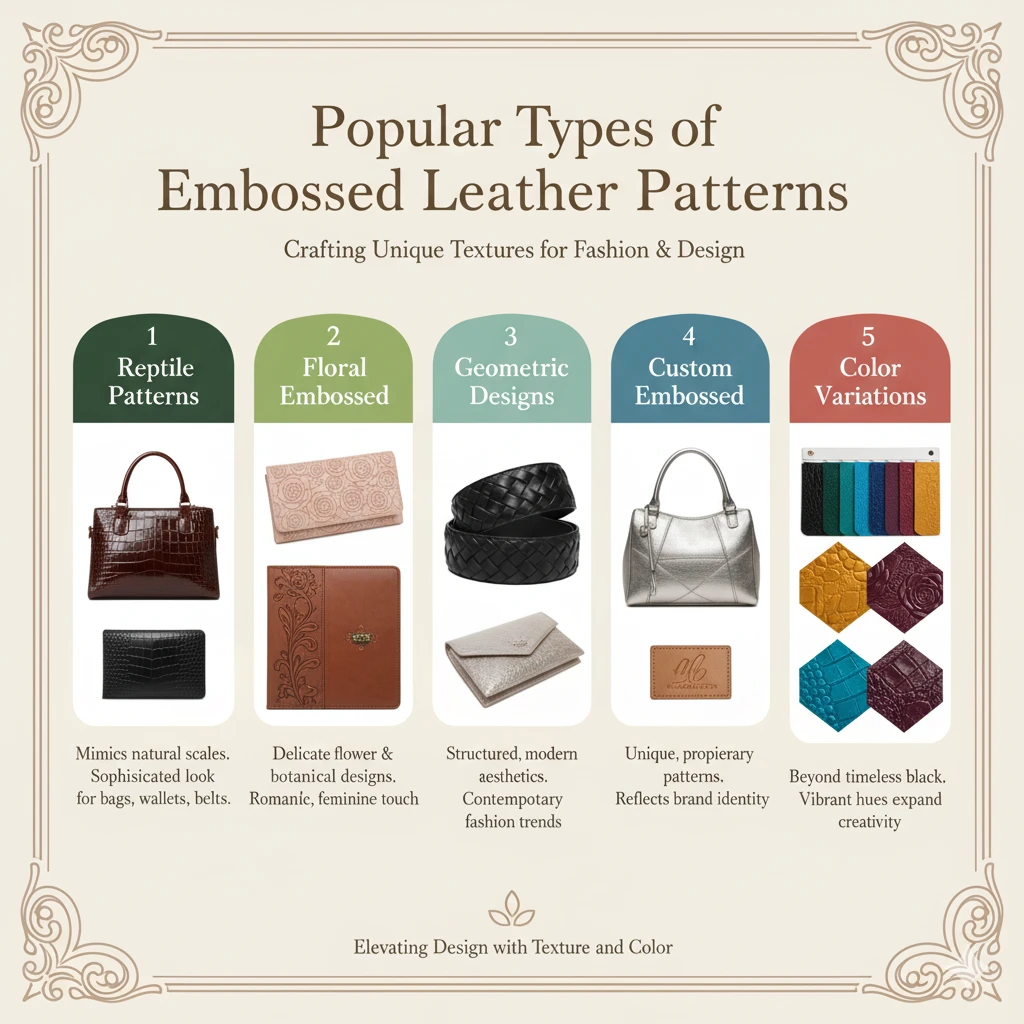

Popular Types of Embossed Leather Patterns

The variety of embossed patterns available today is truly remarkable. Here are the most sought-after designs:

Reptile Patterns: Crocodile embossed and alligator embossed designs remain incredibly popular. These patterns closely mimic the natural scale formations found on genuine reptile skins, creating sophisticated looks for handbags, wallets, and belts.

Floral Embossed Leather: Delicate flower patterns and botanical designs add romantic, feminine touches to accessories. Floral embossed leather works beautifully for clutches, decorative bags, and small leather goods.

Geometric Designs: Diamond patterns, basket weaves, and other geometric motifs provide modern, structured aesthetics that suit contemporary fashion trends.

Custom Embossed Leather: Brands increasingly request unique, proprietary patterns that reflect their identity. Custom embossing creates exclusive designs unavailable anywhere else.

Color Variations: While black embossed leather maintains timeless elegance, manufacturers now offer vibrant colors from turquoise to burgundy, expanding creative possibilities.

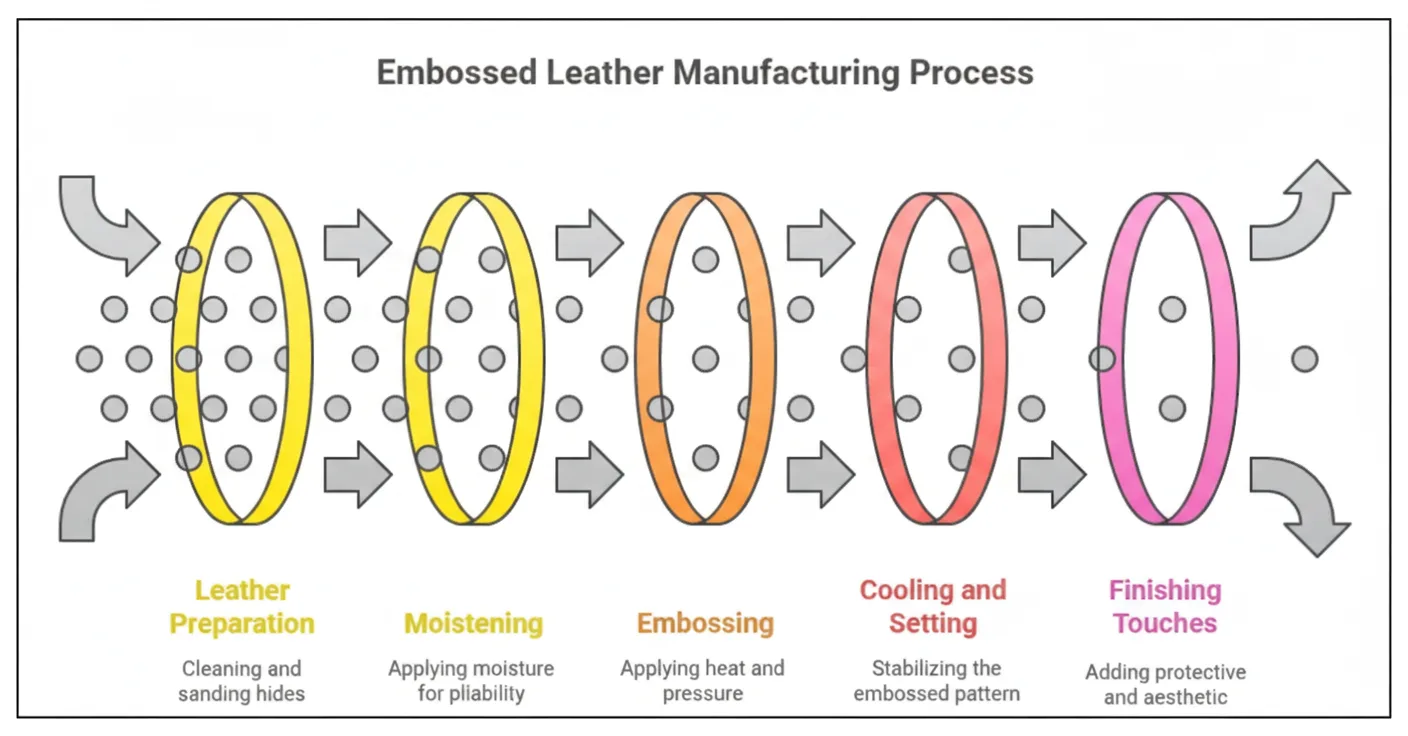

How is Embossed Leather Made? The Complete Process

Now let's explore the actual manufacturing steps that transform plain leather into beautifully textured material.

Step 1: Leather Selection and Preparation

The process begins with choosing appropriate hides. Manufacturers typically select cowhide, lambskin, or buffalo leather as base materials for embossing. The leather must be properly tanned and prepared before embossing begins.

For large-scale production, tanneries sand the leather surface to create uniform texture. This preparation ensures the embossing pattern transfers cleanly and consistently across the entire hide.

Step 2: Moistening the Leather

Moisture plays a crucial role in successful embossing. Manufacturers dampen the leather using distilled water applied with sponges or spray bottles. The moisture content affects how deeply and clearly the pattern imprints.

Damp leather becomes more pliable, allowing fibers to expand and accept new shapes. Chrome-tanned and vegetable-tanned leathers respond particularly well to this preparation step.

Step 3: Applying Heat and Pressure

This step represents the heart of the embossing process. Manufacturers use specialized machines equipped with heated metal plates or rollers that contain the desired pattern engraved in reverse.

The leather passes through these machines where intense pressure combined with controlled heat physically reshapes the surface. Temperature settings typically range between specific thresholds that vary based on leather type and thickness.

Step 4: Creating the Pattern (Methods)

Two primary techniques accomplish the actual embossing:

Plate Embossing: Metal plates measuring approximately 56 inches by 36 inches press down on sections of the hide. This method works well for smaller areas and creates deeply defined impressions. Due to longer contact time, plate embossing produces more durable, stable patterns.

Roller Embossing: Engraved rollers continuously imprint patterns as leather feeds through the machine. This technique handles larger surface areas efficiently, though it typically creates lighter impressions compared to plate methods.

Both approaches have advantages depending on the desired outcome, production volume, and pattern complexity.

Step 5: Cooling and Setting

After embossing, the leather must cool gradually to lock the pattern permanently. Rushing this phase can cause patterns to flatten or distort. Manufacturers sometimes apply additional moisture during cooling to stabilize the embossed motifs further.

For deeply embossed designs, craftspeople may add backing materials or fillers to maintain pattern depth and prevent flattening during product assembly.

Step 6: Finishing Touches

The final stage involves inspection, trimming, and additional treatments. Manufacturers may apply protective coatings, dyes, or finishing solutions that enhance appearance and durability.

Some products receive blind embossing (no added color), while others get color imprints that create contrast within the embossed areas. Gold embossing adds metallic accents for luxury items.

What Factors Determine Embossing Quality?

Four critical parameters control the final result:

Pressure: Higher pressure creates stronger, more defined, and longer-lasting embossed patterns. Insufficient pressure produces shallow impressions that may fade with use.

Temperature: Hotter tools generate darker, more pronounced embossing. The heat slightly burns the leather, creating natural contrast that highlights pattern details.

Duration: Longer contact time between the embossing tool and leather surface yields more stable patterns. Quick processing may save time but compromises durability.

Moisture Content: Properly dampened leather accepts embossing more readily and retains patterns better than dry or oversaturated material.

Balancing these factors requires expertise and experience. Skilled manufacturers adjust settings based on leather type, thickness, and desired pattern characteristics.

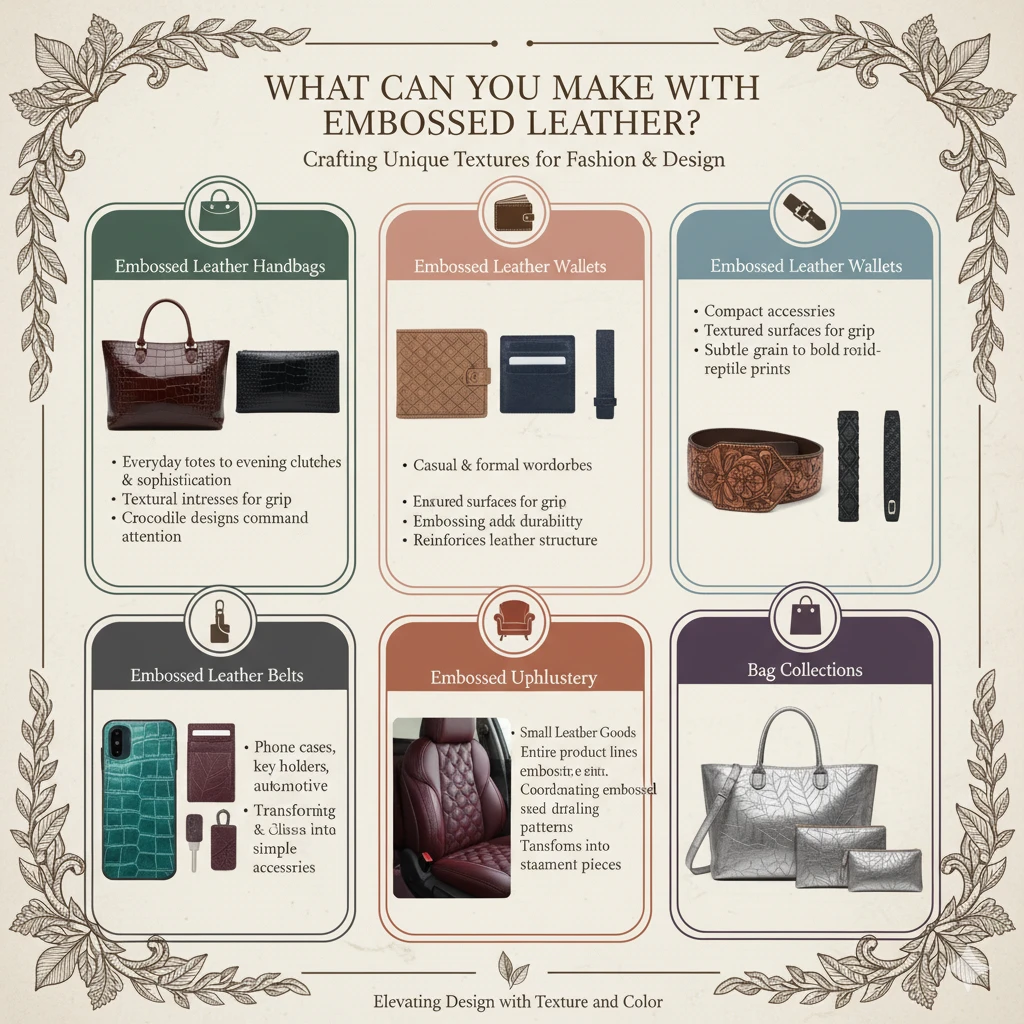

What Can You Make with Embossed Leather?

The versatility of embossed leather makes it suitable for countless applications:

Embossed Leather Handbags: From everyday totes to evening clutches, embossed patterns add visual interest and sophistication. Crocodile embossed leather handbags particularly command attention in fashion circles.

Leather Embossed Bag Collections: Designers create entire lines featuring coordinating embossed patterns across different bag styles, ensuring cohesive brand aesthetics.

Embossed Leather Wallets: Compact accessories benefit greatly from textured surfaces that provide grip and style. Embossed leather wallet designs range from subtle grain patterns to bold reptile prints.

Embossed Leather Belts: Textured belts complement both casual and formal wardrobes. The embossing adds durability by reinforcing the leather structure.

Upholstery: Furniture makers use embossed leather fabric for chairs, sofas, and automotive interiors where durability and visual appeal matter equally.

Small Leather Goods: Phone cases, key holders, and cardholders all benefit from embossed detailing that elevates simple accessories into statement pieces.

How Does Embossed Faux Leather Compare?

Beyond genuine leather embossing, manufacturers also produce embossed faux leather using synthetic materials like polyurethane. This option provides:

-

Even lower costs than embossed genuine leather

-

Vegan-friendly alternatives for conscious consumers

-

Easier maintenance and cleaning requirements

-

Consistent patterns without natural variations

However, embossed faux leather typically doesn't match the durability, breathability, or luxurious feel of genuine embossed leather products.

Is Embossed Leather Worth Buying?

Absolutely! Embossed leather products offer excellent value for several reasons:

They cost significantly less than genuine exotic leathers while providing similar aesthetics. An authentic crocodile handbag might cost thousands, while a crocodile embossed leather handbag delivers comparable style at a fraction of the price.

Maintenance remains simpler compared to delicate exotic skins. Embossed patterns hold up well against regular use, requiring only basic leather care routines.

Ethical shoppers appreciate that embossing reduces demand for endangered species while eliminating concerns about wildlife conservation and CITES certification requirements.

The variety of available patterns, colors, and finishes ensures everyone finds options matching their personal style preferences.

Caring for Your Embossed Leather Products

Proper maintenance extends the life of embossed leather items:

-

Clean regularly with damp cloths to remove surface dirt

-

Apply leather conditioner every few months to maintain suppleness

-

Store away from direct sunlight to prevent fading

-

Avoid excessive moisture that could distort embossed patterns

-

Use protective sprays to guard against stains and water damage

With appropriate care, quality embossed leather bag, wallet, or belt collections remain beautiful for years of enjoyment.

Final Thoughts

Understanding the meticulous process behind creating embossed leather from selecting the finest materials to the intricate embossing techniques highlights the artistry and precision involved. Whether it's the luxurious patterns of crocodile or alligator embossed leather, the timeless appeal of floral designs, or the sleek sophistication of black embossed leather, each piece tells a story of craftsmanship and innovation.

At Rock Uniquoters, we pride ourselves on being at the forefront of synthetic leather manufacturing. Our flagship brand, Arton, offers a diverse range of embossed faux leather options, combining traditional techniques with modern design to meet the evolving needs of various industries. From fashion accessories like embossed leather handbags and wallets to automotive interiors and home décor, our products are designed to deliver both aesthetic appeal and durability.

With over 30 embossed designs, 12+ paper patterns, and a palette of 35+ leather colors, we provide unparalleled customization to align with your brand's vision. Our commitment to quality is reflected in our ISO-certified manufacturing processes and timely delivery across more than 40 countries.

Explore our collection and discover how Rock Uniquoters can elevate your products with premium embossed leather solutions. Visit our website to learn more and connect with our team for tailored leather options that suit your specific needs.

Frequently Asked Questions About Embossed Leather

1. What is the difference between embossed leather and natural textured leather?

Embossed leather is artificially stamped to create a pattern, whereas natural textured leather, like genuine crocodile skin, develops its texture naturally during growth.

2. Can faux leather be embossed?

Yes! Embossed faux leather can replicate patterns like crocodile embossed leather or floral motifs while being more affordable and animal-friendly.

3. How do you maintain embossed leather products?

Regular cleaning with a damp cloth, occasional conditioning, and avoiding prolonged exposure to sunlight will keep embossed leather bags and wallets looking new.

4. Is custom embossed leather durable?

Yes, when made from high-quality leather and properly finished, custom embossed leather products like wallets and belts are long-lasting and resistant to wear.