01 December, 2025

When buying leather products whether bags, belts, wallets, footwear, or upholstery one factor affects almost everything: leather thickness. The thickness of leather directly influences durability, flexibility, weight, and long-term performance. Choosing the wrong thickness can make a handbag too flimsy, a belt too weak, or upholstery too stiff.

Today, buyers also increasingly choose synthetic leather and faux leather because they offer greater consistency, lower cost, and eco-friendly production options. These materials allow manufacturers to maintain precise thickness levels, making them highly suitable for modern accessories and fashion goods.

Understanding how leather thickness works will help you choose the perfect material for your next purchase whether you want lightweight everyday items or sturdy long-lasting products.

What Is Leather Thickness and How Is It Measured?

Leather thickness refers to how thin or thick a leather material is, which directly affects its durability, flexibility, weight, and ideal end use. Whether you're buying natural, synthetic leather, or faux leather, understanding thickness helps you choose the right material for bags, footwear, belts, or accessories.

Leather thickness is commonly measured in two units:

-

Millimeters (mm): The global standard used by most manufacturers.

-

Ounces (oz): A traditional leathercraft measurement (1 oz ≈ 0.4 mm).

Natural hides often show variation in thickness across different areas. In contrast, faux synthetic leather provides uniform, consistent thickness, making it easier for brands to achieve stable quality, smooth production, and predictable performance.

This knowledge forms the foundation of any leather thickness guide, especially when comparing materials for different types of fashion and lifestyle products.

Leather Thickness Ranges and Their Applications

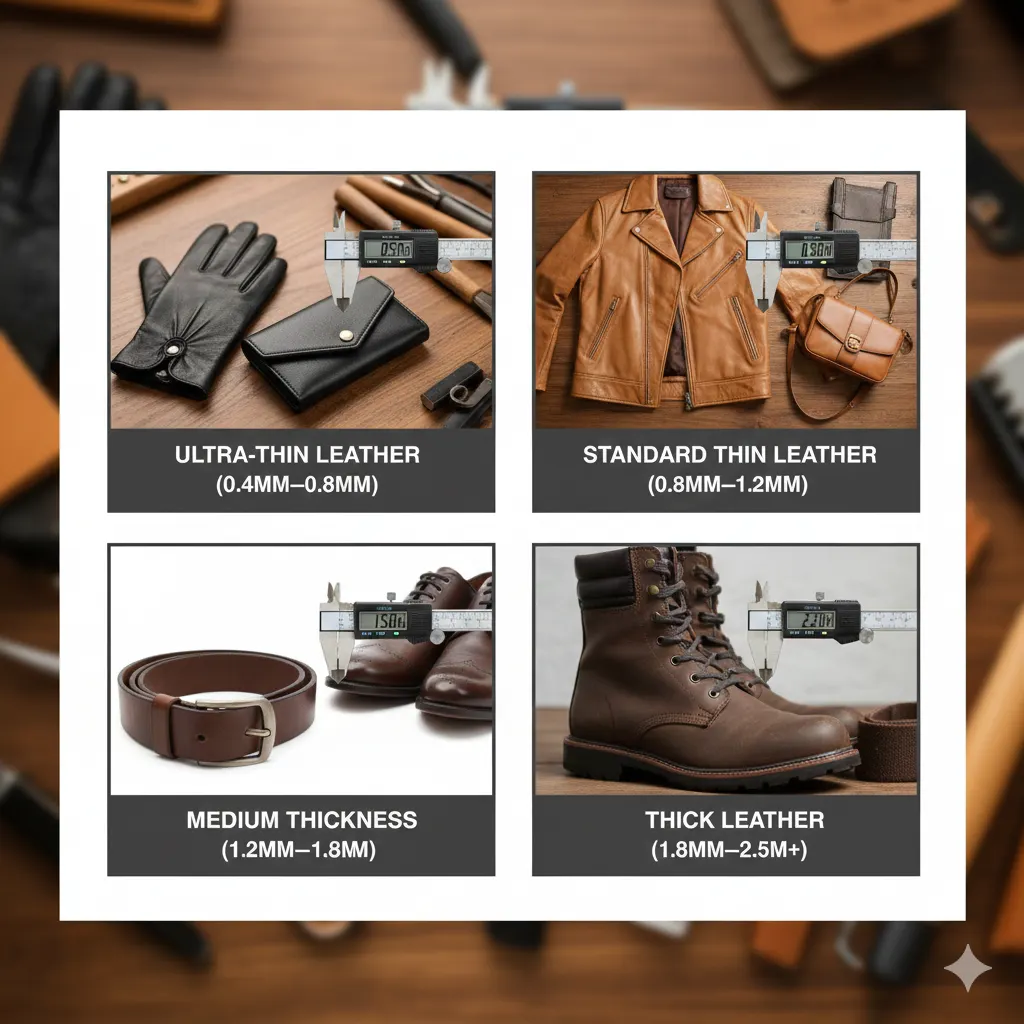

1. Ultra-Thin Leather (0.4mm–0.8mm)

Ultra-thin leather is lightweight, soft, and flexible ideal for:

-

Garment linings

-

Small fashion components

-

Soft accessories

-

Decorative overlays

Best for styles that prioritize comfort rather than structure.

2. Standard Thin Leather (0.8mm–1.2mm)

This is the most versatile thickness range and is used for:

-

Wallets

-

Clutches

-

Watch straps

-

Small leather goods

-

Light trims on handbags

This is also an ideal leather thickness for bags that are compact and flexible.

3. Medium Thickness (1.2mm–1.8mm)

Great for items that need durability without feeling too heavy.

Used for:

-

Everyday handbags

-

Light footwear

-

Leather jackets

-

Medium-size accessories

4. Thick Leather (1.8mm–2.5mm+)

This is the preferred range for heavy-duty and structured items, including:

-

Belts

-

Larger structured bags

-

Luggage

-

Footwear requiring support

-

Furniture upholstery

This category includes thick faux leather, which is widely used in upholstery and durable fashion goods.

Leather Thickness Chart: Quick Buyer Reference

| Product Type | Ideal Leather Thickness | Why It Works |

|---|---|---|

| Wallets | 0.8–1.2mm | Slim profile fits pockets comfortably; maintains flexibility for frequent opening/closing. |

| Small Handbags | 1.0–1.4mm | Balanced body and softness; light enough for all-day carry with adequate structure. |

| Large Bags | 1.4–2.0mm | Provides structure and strength; supports weight of contents without sagging. |

| Belts | 1.8–2.5mm | High load-bearing capacity; resists stretching at buckle stress points. |

| Shoes | 1.2–1.8mm | Supportive yet flexible; allows natural foot movement while protecting feet. |

| Upholstery | 1.5–2.2mm | Durability for high-traffic use; comfort for extended sitting; maintains appearance. |

| Clutches | 0.6–1.0mm | Elegant lightweight design; easy to hold; emphasizes refined aesthetics. |

| Backpacks | 1.5–2.2mm | Durability for daily contents; shoulder strap support; weather resistance. |

| Luggage | 2.0–2.8mm | Heavy-duty construction; abrasion resistance; handles rough transport. |

Thin vs Thick Leather: Which Should You Choose?

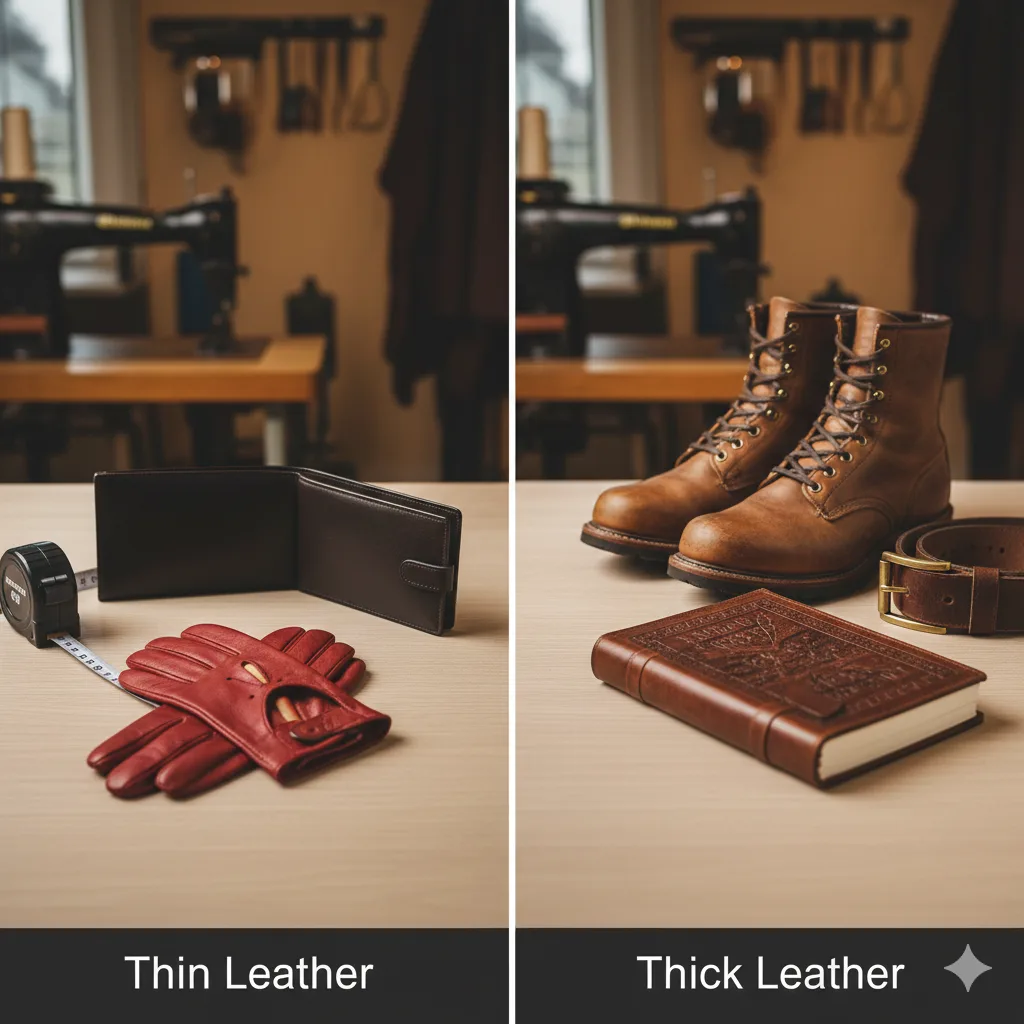

When Thin Leather Is Better

-

Flexibility Requirements

Choose thin leather when products need to bend, fold, or conform to curved surfaces. Wallets folding in half, clutches tucking under arms, or gloves following hand movements all benefit from thin, pliable materials that move naturally without resistance.

-

Lightweight Items

Products worn or carried for extended periods watch straps, small crossbody bags, lightweight jackets perform best with thin construction. Every additional millimeter adds weight that becomes noticeable during all-day use.

-

Fashion Accessories with Intricate Shaping

Detailed design work, including pleating, gathering, or complex stitching patterns, requires thin faux leather that manipulates easily. Thick materials resist these techniques, limiting creative possibilities and increasing manufacturing difficulty.

-

Cost Optimization

When budget constraints matter significantly, thin materials reduce costs per finished product while still delivering acceptable performance for appropriate applications. Strategic thickness selection maximizes value without compromising essential functionality.

When Thick Leather Is Better

- Durability Requirements

Products facing heavy use, rough handling, or harsh environments need thick construction. Luggage thrown by baggage handlers, work boots on construction sites, or commercial furniture in restaurants all justify the investment in substantial thickness.

- Heavy Load Products

Items carrying significant weight large tote bags, messenger bags with laptops, or backpacks with books require thick synthetic leather that won't stretch or deform under stress. The structural integrity prevents sagging and maintains shape through years of loaded use.

- Items Needing Structure and Shape

Structured handbags maintaining defined silhouettes, professional briefcases conveying authority, or belts holding pants securely all depend on thickness for proper performance. Thin materials simply cannot provide the necessary support for these applications.

- Premium Positioning

Luxury markets associate substantial weight with quality. Thick leather feels expensive in hand, suggesting craftsmanship and longevity that justify premium pricing. When perceived value matters, thickness contributes to the overall impression of excellence.

How Synthetic & Faux Leather Solve Thickness Problems

Consistent Thickness for Manufacturers

Unlike animal hides, synthetic leather does not have natural irregularities.

This ensures:

-

Uniform thickness

-

Faster production

-

Smooth cutting and stitching

-

Fewer defects and wastage

Perfect for brands needing precision and consistency.

Ideal for Modern Fashion & Accessories

Faux leather and faux synthetic leather are popular because they offer:

-

Durability

-

Weather resistance

-

Eco-friendly manufacturing options

-

Affordable pricing

-

A wide range of thickness options

-

Modern textures and finishes

These materials maintain controlled thickness while still delivering a premium look.

How to Choose the Right Leather Thickness (Step-by-Step Guide)

1. Identify the Product’s Purpose

-

Heavy-duty use: Choose thicker material

-

Decorative or fashionable: Use thinner, flexible leather

2. Consider the Stitching & Construction

Thin leather works well for sewing small goods, while thicker leather requires heavy-duty stitching and reinforced edges.

3. Check Structural Requirements

Ask yourself:

-

Should the product stand upright?

-

Will it carry heavy items?

-

Does it need to bend easily?

4. Select the Right Material Type

Modern synthetic leather, faux leather, and faux synthetic leather provide:

-

Uniform thickness

-

Affordable pricing

-

Weather resistance

-

Eco-friendly manufacturing

This makes them ideal substitutes for real leather without compromising performance.

5. Review Thickness Based on Stress Points

For bags:

-

Body: Medium thickness

-

Handles: Thicker reinforcement

-

Linings: Thin, flexible material

Using the correct layering enhances longevity and comfort.

Common Mistakes Buyers Make (and How to Avoid Them)

1. Choosing Based on Appearance Alone

Beautiful surface finishes can disguise inadequate thickness. A gorgeous embossed pattern on 0.8mm material won't perform in a belt application requiring 2.0mm. Always verify thickness specifications before purchasing based on aesthetics alone.

2. Ignoring Product Usage

Selecting "standard" thickness without considering actual use conditions leads to premature failure. A messenger bag carrying laptops daily needs different specifications than a decorative wall hanging, even if both are "bags."

3. Not Checking Thickness Specifications

Assuming "leather" means appropriate thickness for your needs invites disappointment. Always request and verify exact millimeter measurements never rely on vague descriptors like "medium weight" or "standard thickness."

4. Confusing Natural and Synthetic Thickness Behavior

Natural leather may compress or stretch over time, effectively reducing thickness. High-quality synthetic leather maintains dimensional stability better, meaning specified thickness remains consistent throughout product life. Factor these behavioral differences into selection decisions.

5. Overlooking Reinforcement Needs

Thin materials can work in applications typically requiring thickness if properly reinforced. Strategic placement of interfacing, backing materials, or structural elements allows using preferred aesthetics while meeting performance requirements. Don't automatically dismiss thin options without considering reinforcement possibilities.

6. Assuming Price Indicates Appropriate Thickness

Expensive doesn't automatically mean thick, nor does budget-friendly guarantee thin. Verify actual specifications rather than inferring thickness from pricing. Sometimes premium pricing reflects brand positioning, special finishes, or exclusive designs rather than material substance.

Explore Leather Thickness Guide

Conclusion

Understanding leather thickness transforms how you evaluate and purchase leather products or materials. This comprehensive leather thickness guide demonstrates that thickness isn't merely a specification it fundamentally determines product performance, longevity, and suitability for intended applications.

Whether choosing slim 0.8mm material for elegant wallets or robust 2.2mm construction for durable luggage, matching thickness to purpose ensures satisfaction and value. Synthetic leather and faux leather offer remarkable advantages for modern buyers: consistent thickness across production runs, extensive range options, and reliable performance that natural alternatives struggle to match.

Armed with this knowledge, approach leather purchases confidently, demanding precise specifications and verifying actual measurements. The right thickness choice makes the difference between products that disappoint and those that exceed expectations for years to come.

Frequently Asked Questions (FAQ)

1. What is the best leather thickness for bags?

For everyday bags, 1.2–1.8mm works best. For structured bags, consider 1.6–2.0mm.

2. Does thickness affect durability?

Yes. Thicker leather generally lasts longer, especially for belts and large bags.

3. Is thicker faux leather better for belts?

Yes. Thick faux leather (1.8–2.5mm) provides excellent support and buckle strength.

4. How do I measure leather thickness at home?

Use a digital caliper for accurate millimeter measurement, or compare using a standard thickness card.

5. Is synthetic leather available in multiple thickness options?

Absolutely. Synthetic leather can be manufactured in everything from 0.4mm to over 2.5mm.